In today’s fast-paced business environment, flexibility and adaptability are no longer optional—they are essential traits for organisations aiming to survive and thrive. From shifting market trends to unexpected supply chain disruptions, companies face challenges that demand agile thinking. Surprisingly, one of the best metaphors for understanding these qualities comes from an unlikely source: the Flex-Turn Conveyor. This seemingly simple piece of equipment in logistics offers lessons on navigating complexity with efficiency and foresight.

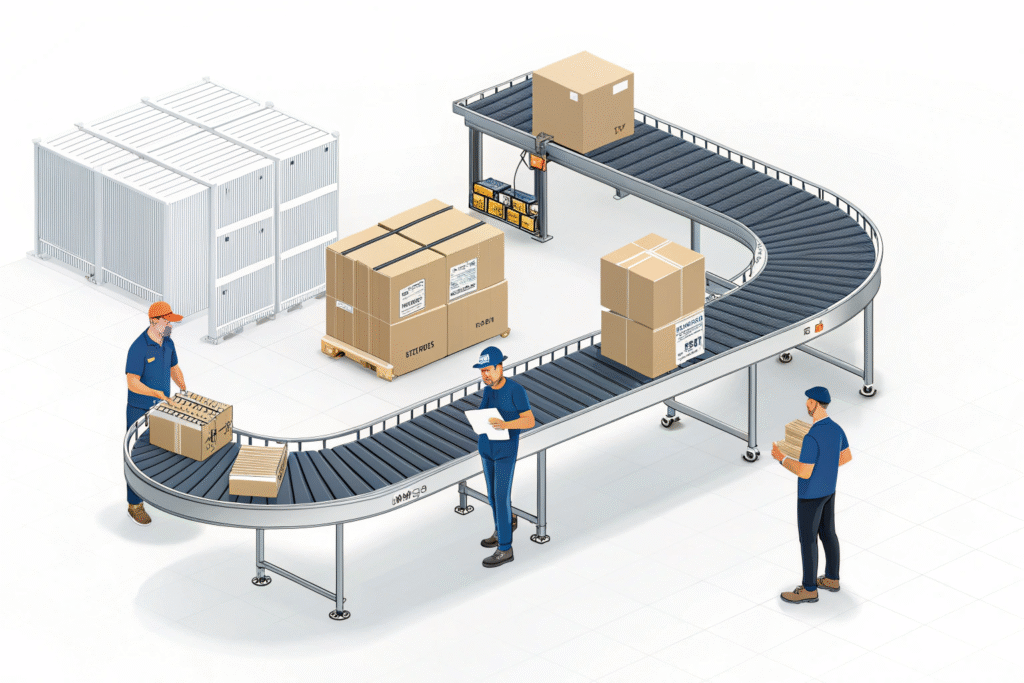

At its core, a Flex-Turn Conveyor is designed to move products around corners and curves without interrupting the flow of operations. Unlike traditional straight-line conveyors, it adapts to different angles, layout changes, or evolving operational requirements. Its ability to handle turns smoothly, without slowing down, is a powerful illustration of what flexibility in business truly entails. Just as a Flex-Turn Conveyor adjusts to spatial constraints, organisations must navigate changing market conditions without losing momentum.

One key lesson from the Flex-Turn Conveyor is the importance of anticipating change. These conveyors handle complex paths, multiple product types, and varying speeds. Similarly, adaptable businesses plan for multiple scenarios. They anticipate potential disruptions, understand emerging customer needs, and prepare systems that allow quick pivots. A mindset of proactive planning ensures that when challenges arise, companies can adjust strategies without halting operations.

Another insight is resilience through design. Flex-Turn Conveyors are built with flexibility in mind—they can expand, contract, or reconfigure as necessary. In business, resilience stems from designing processes and teams that absorb shocks and continue functioning under pressure. Cross-functional teams, modular workflows, and scalable processes allow organisations to redistribute resources quickly when circumstances change. Just as the conveyor prevents bottlenecks, resilient businesses maintain flow even in uncertainty.

The ability to maintain momentum despite obstacles is another lesson. In material handling, products must move around curves without tipping or slowing. Translating this to business, organisations must continue progressing even amid disruptions like regulatory changes or supply shortages. Adaptable companies implement alternative strategies, allocate resources efficiently, and ensure projects advance toward goals without unnecessary delays.

The Flex-Turn Conveyor also highlights the importance of integration and alignment. Each segment of the system works seamlessly with the rest, ensuring smooth flow. Similarly, adaptability in business involves aligning changes across all areas of operation. Departments, teams, and processes must communicate effectively so adjustments in one area do not create bottlenecks elsewhere. When strategy, communication, and execution are harmonised, organisations can bend without breaking, much like a well-designed conveyor.

Continuous improvement and learning are another dimension. Modern conveyors are upgraded with sensors, automation, and monitoring systems to optimise performance. Likewise, adaptable businesses learn from past experiences, analyse performance, and iterate processes to meet evolving needs. Flexibility requires ongoing refinement and a willingness to innovate, ensuring the organisation stays ahead in a changing landscape.

The human element is equally critical. Even the most advanced conveyor system requires skilled personnel to oversee operations, troubleshoot, and optimise flow. Similarly, adaptable businesses rely on empowered employees who make informed decisions and embrace change. Investing in training, fostering a culture of experimentation, and encouraging problem-solving equips teams to respond quickly when circumstances shift. People, like conveyor components, must work in sync to keep operations moving.

Also Read:Tcintikee: Transforming Ideas Into Real-World Innovation

A practical takeaway is modular thinking. Flex-Turn Conveyors often consist of interchangeable parts, allowing modifications as needed. Businesses can adopt a similar approach by structuring processes and assets modularly. Digital platforms, cloud-based tools, and modular supply chains provide the flexibility to scale operations or pivot services without major downtime. By thinking in modules rather than rigid structures, companies respond more fluidly to market dynamics.

Finally, the Flex-Turn Conveyor demonstrates that efficiency and flexibility are not mutually exclusive. Some organisations believe adaptability requires sacrificing efficiency, or that streamlined processes limit responsiveness. In contrast, the conveyor shows that systems can be both efficient and flexible. Companies that build adaptable strategies while optimising resources navigate change swiftly while maintaining productivity. Balancing agility with operational excellence is key to long-term success.

In conclusion,

the humble Flex-Turn Conveyor offers more than a solution for moving products it serves as a rich metaphor for business flexibility and adaptability. From anticipating change and maintaining momentum to fostering integration, resilience, and modular thinking, there are lessons for any organisation seeking to thrive in 2025 and beyond. By embracing these principles, companies remain agile, respond effectively to challenges, and sustain growth.

Brands like Wirebelt, pioneers in advanced conveyor systems, exemplify how thoughtful design in operational tools can provide valuable lessons for the broader business world. Just as their Flex-Turn Conveyors keep products moving smoothly, businesses can keep strategies and operations flowing efficiently through planning, adaptability, and continuous improvement.