Introduction: What is a Heavy Alloy Penetrator?

A heavy alloy penetrator is a type of high-density, high-velocity projectile specifically engineered to defeat modern armored targets such as tanks, fortified bunkers, and armored vehicles. These penetrators are the backbone of kinetic energy (KE) weapons, where mass and speed are key to penetrating armor. Commonly made from tungsten heavy alloys (WHA) or depleted uranium (DU), these projectiles are designed to concentrate maximum energy on a small point of impact, making them ideal for armor-piercing applications.

The Purpose of the Heavy Alloy Penetrator Project

The goal of the Heavy Alloy Penetrator Project is to develop advanced armor-piercing munitions with greater penetration capabilities, improved accuracy, and environmental safety. As armored threats evolve with composite and reactive armor systems, this project aims to stay ahead by engineering penetrators that are more effective, efficient, and ethically manufactured.

Heavy Alloy Penetrator Project, Trichy

The Heavy Alloy Penetrator Project (HAPP) is located in Tiruchirapalli (Trichy), Tamil Nadu, India. It operates under the Ordnance Factory Board (OFB), now reorganized as part of Advanced Weapons and Equipment India Limited (AWEIL). HAPP Trichy specializes in manufacturing high-precision penetrators used in APFSDS rounds for the Indian Armed Forces.

This unit plays a crucial role in India’s defense sector by delivering indigenously developed heavy alloy penetrators, reducing dependence on foreign suppliers. Its advanced manufacturing capabilities make it one of the few facilities in India capable of producing such sophisticated ballistic components.

Heavy Alloy Penetrator Project Tiruchirapalli Contact Number

For direct communication or business inquiries, you can contact the Heavy Alloy Penetrator Project, Tiruchirapalli using the official government channels. While contact details may vary, the standard method is through the Department of Defence Production or AWEIL’s central office.

You can also reach them at:

- Phone: +91 431 2581801 (General Enquiry)

- Address: Heavy Alloy Penetrator Project, OFT Road, Trichy – 620016, Tamil Nadu, India

- Email: Use the official directory at https://ddpdoo.gov.in to find specific departments

Always verify with official sources before contacting.

HAPP Trichy Website

HAPP Trichy’s digital presence is part of the Indian Government’s defense manufacturing portal. While it doesn’t have a standalone website, information about HAPP can be accessed through:

- Official Portal: https://ddpdoo.gov.in/units/HAPP

- Parent Organization: Advanced Weapons and Equipment India Limited (AWEIL)

On this portal, you’ll find product catalogues, vendor registration forms, tenders, and contact information relevant to HAPP’s operations.

HAPP Trichy Products

HAPP Trichy produces a range of strategic military hardware, with a primary focus on armor-piercing and kinetic energy munitions. Key products include:

- APFSDS Penetrators (Armor Piercing Fin Stabilized Discarding Sabot)

- Tungsten Alloy Rods for tank ammunition

- Composite Penetrators for upgraded main battle tanks

- Prototype penetrators for research and trials

- Customized alloy rounds for testing against new armor technologies

These products serve both Indian and allied defense forces, reinforcing India’s commitment to Atmanirbhar Bharat (self-reliance) in defense manufacturing.

Material Development: The Core of Penetrator Design

Tungsten Heavy Alloys (WHA)

Tungsten, with a density of 19.3 g/cm³, is a preferred material for KE penetrators. When alloyed with elements like nickel, iron, or cobalt, it becomes more machinable and impact-resistant. These alloys maintain structural integrity upon impact, allowing deeper armor penetration.

Depleted Uranium (DU)

DU offers self-sharpening properties on impact, making it superior in performance but controversial due to radioactivity and toxicity. Some defense agencies are phasing out DU in favor of eco-friendlier alternatives.

Emerging Alternatives

Recent R&D focuses on nanostructured tungsten alloys, ceramic-metal composites (cermets), and eco-safe binders to reduce the environmental footprint without compromising performance.

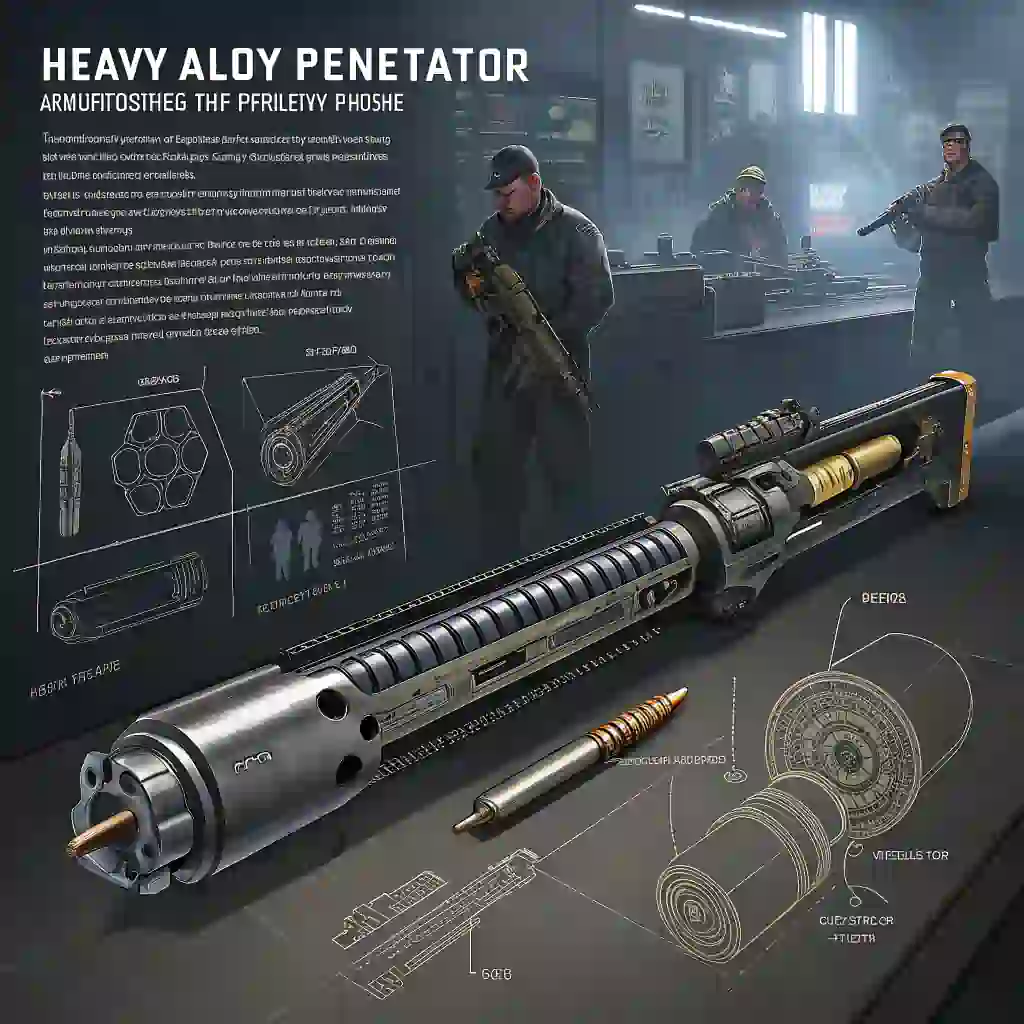

Advanced Projectile Design Features

The modern heavy alloy penetrator is a long-rod projectile, typically housed within an Armor-Piercing Fin-Stabilized Discarding Sabot (APFSDS) system. Key design components include:

- Long-rod geometry for high kinetic energy concentration

- Fins for stabilization and improved in-flight accuracy

- Discarding sabot to enhance velocity and reduce air resistance

These design elements contribute to greater armor penetration efficiency, even at long ranges or against angled surfaces.

Manufacturing Techniques for High-Performance Penetrators

To achieve optimal performance, the Heavy Alloy Penetrator Project employs:

- Powder metallurgy for uniform microstructure

- Hot isostatic pressing (HIP) to reduce porosity

- Precision CNC machining for aerodynamic shaping

- Vacuum sintering for improved mechanical properties

These methods ensure high density, low impurity levels, and consistent behavior under stress.

Testing and Simulation: Ensuring Real-World Effectiveness

Every penetrator undergoes rigorous ballistics testing against targets with conventional, composite, and reactive armor. Simulations using Finite Element Analysis (FEA) and hydrocode modeling allow engineers to:

- Predict behavior at various velocities and angles

- Optimize rod length and tip geometry

- Improve survivability against countermeasures

Live-fire trials validate these models, ensuring the penetrator’s effectiveness in real combat scenarios.

Environmental and Ethical Considerations

As global defense standards evolve, so does the need for sustainable and safe munitions. The Heavy Alloy Penetrator Project is working to:

- Replace DU with non-toxic tungsten alloys

- Use eco-friendly binders and manufacturing processes

- Reduce long-term environmental contamination

These improvements align with NATO guidelines and international treaties focused on reducing the ecological impact of military operations.

Applications in Modern Warfare

Heavy alloy penetrators are crucial in:

- Tank-mounted cannons (e.g., M1 Abrams, Leopard 2)

- Artillery systems for long-range strikes

- Air-to-ground munitions (e.g., A-10 Warthog cannon shells)

- Anti-materiel sniper rounds

Their performance against reactive and composite armor makes them essential in modern and future battlefields.

Defense Agencies and Research Institutions

This project often collaborates with:

- U.S. Army Research Laboratory

- Defense Advanced Research Projects Agency (DARPA)

- BAE Systems, Rheinmetall, Raytheon, and other contractors

- Universities and R&D centers in materials science

These partnerships accelerate innovation and translate lab research into battlefield-ready solutions.

Future Directions and Innovations

Looking ahead, the Heavy Alloy Penetrator Project is exploring:

- AI-driven simulations for material behavior prediction

- Additive manufacturing (3D printing) for complex sabot structures

- Smart materials that adapt during impact

- Reduced-sig penetrators for stealth operations

Such innovations aim to maintain battlefield superiority while adhering to ethical and environmental standards.

Also Read:Rachel Reeves Net Worth 2025: Inside the $2 Million Fortune of the UK Chancellor

(FAQs)

Q: What are heavy alloy penetrators made of?

A: Typically, they are made from tungsten heavy alloys or depleted uranium due to their extreme density and strength.

Q: What is the purpose of a sabot in penetrator rounds?

A: The sabot holds the penetrator in the barrel and discards mid-flight to reduce drag and increase velocity.

Q: Are depleted uranium penetrators still in use?

A: While some militaries continue to use DU rounds, many are shifting to eco-friendly tungsten-based alternatives.

Q: Why is tungsten preferred in penetrator projects?

A: Tungsten has a very high density, excellent mechanical strength, and is less toxic than depleted uranium.

Q: How are heavy alloy penetrators tested?

A: Through a combination of live-fire trials, computer simulations, and impact tests against various armor types.

Conclusion

The Heavy Alloy Penetrator Project represents a fusion of materials science, military engineering, and ethical innovation. By focusing on cutting-edge tungsten alloys, precision design, and eco-conscious production, the project aims to revolutionize armor-piercing technology for modern warfare. As threats evolve, so must our solutions—and this project ensures armed forces remain a step ahead with smarter, stronger, and safer munitions.